This article is brought to you by Lizzsews.

GCODE -> Geometric Code

The language that tells a machine what and how to do something. The file tells the machine what path to follow, where to move, how fast to move, and more.

This software programming language is used to control CNC machines- including 3D printers.

When downloading or creating 3D models, you are often left with an STL or OBJ file. These files are not compatible with and cannot be read by your machine. It needs to be 'translated' for your printer to print it.

Recommended read: What is an STL file

\

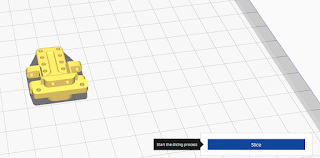

Translating = slicing

When you slice your STL or OBJ files, you receive a GCODE file. This file can now be read by your machine and contains commands for your machine. The file tells your 3D printer what parts to move within.

Recommended read: What is slicing in the 3D printing world

When slicing your 3D print model, you set your settings in slicing software. These settings determine what code will be written in the GCODE file. Everything from the speeds, starting/ending points, temperatures, retraction, exact print paths, and more.

Recommended read: What I use to slice my 3D print files

The GCODE file is a string of code that can be read by your 3D printer.

Leave a comment below and let me know if you now know why a GCODE file must be created from the STL file! And don't forget to subscribe to stay up to date with all of Lizzsews new articles. See you next time!

Fun Fact: Most printing commands begin with the letter G; this is where the name 'G-Code' comes from!

Comments

Post a Comment